Contributing Editors: J. Boen and A. Breckenridge

So far, we have been writing about the advances in sustainability created from industrial biotechnology and the benefits it brings to our global economy. Nothing is more powerful than a true example of this in action. So, we would like to share our rationale for why we chose to invest in Visolis as an example to bring it home. The technology Visolis brings to bio-based manufacturing offers three key advantages in delivering sustainability throughout the value chain: reduced carbon emissions, utilization of a waste feedstock, and efficiency in biomanufacturing process at scale. While there are many other reasons such as the go to market strategy, fit for the market, economic viability, and the team led by Deepak Dugar, its Founder and CEO (image below), the sustainability benefits are top of mind when we select our companies for investment.

Carbon negative production meets industry sustainability goals

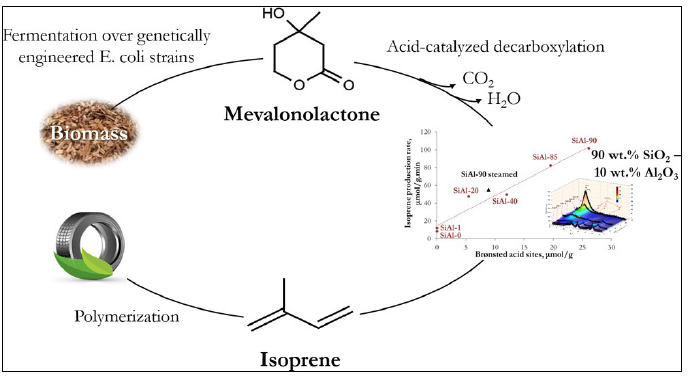

Visolis’ process allows for carbon-negative production of chemical products. For example, a target of Visolis’ platform is the manufacturing of bio-based isoprene. Over 1 million metric tons of isoprene are produced every year from petrochemical feedstocks. It’s the main component of various synthetic rubber formulations, and is used in such products as tires, shoe soles, adhesives, and textiles – encompassing a market in the billions of dollars. Furthermore, the prospect of bio-based isoprene has sparked interest in Visolis from numerous Fortune 500 companies as their drive to achieve net zero goal for the environment and economy. We believe the value proposition Visolis offers the industry on the sustainability front demonstrates a very favorable risk:reward through which multiple partnership opportunities will arise.

Waste feedstock utilization

Both in terms of circularity and long-term cost-effectiveness, utilizing a non-competitive feedstock to our food supply is critical to enable large-scale bioproduction processes. Arguably one of the most influential points in which investors should heed when underwriting an industrial biotech business. Ignoring the feedstock used and its future implication on the success of the bioeconomy would be a severe detriment. A world in which the bioeconomy becomes fully dependent upon food-competitive feedstocks will dramatically drive up food costs to producers and consumers and be economically infeasible at scale. A hard lesson learnt in the biofuel frenzy and should never be forgotten.

When we began meeting with Visolis, our interest peaked as we quickly learned of their ability to utilize waste feedstocks as a raw material source. Visolis’ platform allows for feedstocks ranging from agricultural byproducts to CO2 and hydrogen. The use of cheap feedstocks has allowed Visolis to obtain favorable economics in the overall production costs and margins it is able to attain on its products. This feedstock source provides for long term supply solutions and near term goals in which Visolis could be wildly successful.

Demonstration of biomanufacturing process at scale

Visolis’ technology has been in development for over ten years by the time we invested. What started as a class project in 2012 during Deepak’s time at MIT, culminated in a fellowship at ACTIVATE (https://www.activate.org/) in 2015, which put Visolis on the path it is today. Throughout the initial phases of R&D and scaling, Deepak and team have been able to demonstrate a supreme level of competence and dedication to the business that has allowed Visolis to operate for years without needing the help of VC dollars. In aggregate, they have been able to raise over $18 million in non-dilutive funding in research and foundation grants. By the time Visolis began raising money from First Bight Ventures and other VCs, it had already shown that it could produce its products at a fairly large scale. This allowed them to a) generate revenue from an early stage and b) continually iterate its process to optimize production using the valuable data it was collecting from scaling.

We believe the continuous feedback loop its process embodies (and has embodied since the early days) will allow Visolis to successfully develop multiple valuable assets from its core platform and drive down costs for each over time. Making its business multi-faceted, sustainable, and most importantly, cost-competitive with incumbents. A future in which Visolis technology transforming production of current commodity chemicals will significantly reduce carbon footprint and improve economics in the chemical industry is extremely exciting for Industrial Biology and the world.

Transitioning into our next topic:

Achieving 100% biodegradability with favorable economics is another goal for Industrial Biotechnology which involves creating a completely sustainable path. 100% biodegradability provides humanity with the ultimate circularity, exactly how nature works. In the next blog, we will discuss the new industrial biotechnologies leading to a safer and prosperous new economy and world.

References

- Visolis’ isoprene production paper: https://pubs.acs.org/doi/10.1021/acscatal.0c01438

- Visolis – EU commission grant page: https://cordis.europa.eu/project/id/663118

Recent Comments